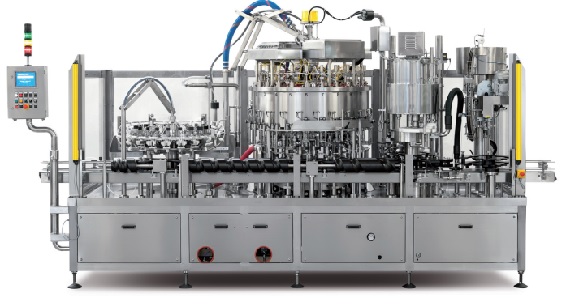

In over 40 years of business activity, FIMER has gained so much experience in the beverage filling sector in general that it is now able to design and implement specific solutions to also cater to special requirements. And thanks to a young, dynamic and flexible management and technical staff, FIMER is also able to find rational solutions for even highly complex needs. There can be no doubt that one of FIMER’s strong points is flexibility.

This technology now also includes filling by the folloiwng means:

Present us with your specific need and we will provide a solution

FIMER equipment is distinguished by the reliability and accuracy put into every build. Quality is guaranteed by the use of cutting-edge solutions which, at the same time, make it possible to achieve functional and reliable systems. Our professional expertise is backed by extensive knowledge and experience as regards applicable standards, which translates into top-quality design, manufacture and maintenance, with the application of Quality Systems in accordance with current regulations. The result is a company that operates with integrity and professionalism, where product and service reliability is paramount.

At Viniquip International we offer a range of services, from over the phone support to on-site one-on-one consultation.

We stock an extensive range of spare parts at our warehouse in Hastings, which are readily available and just a phone call away.